55+ Years Experience

In-House CNC Machining

ISO 9001 Certified Experts

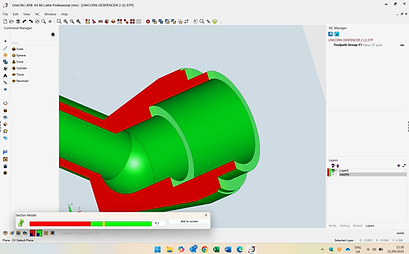

High-Accuracy Turning Using CAD/Cam Technology

We offer multi-axis CNC turning services designed to produce highly accurate cylindrical parts across a wide range of materials. Using advanced CAD/CAM systems and precision toolroom lathes, we machine intricate forms to minute tolerances with ultra-fine finishes. This fully automated process ensures consistent dimensional accuracy and visual quality, making it suitable for complex part production where detail and precision are critical to performance. We handle one-off prototypes, small to medium batches, and production runs for aerospace, oil and gas, and general engineering sectors. Reach out to us to explore your options.

Our CNC Turning Machines

We can machine a wide variety of materials, including stainless steel, aluminium, brass, plastics, and exotic alloys. Services include external and internal turning, thread cutting (metric, imperial, special threads), boring and facing, grooving and parting-off, complex profiles, and precision finishing. Our turning facility features a selection of CNC machines chosen for reliability and precision:

-

1 x Colchester Combi K2

-

1 x Doosan Lynx 220LY

-

1 x Doosan Puma 2600Y BII

-

1 x Puma DNT 2600LM

-

1 x Colchester Tornado 200

-

1 x XYZ SLX425

Quality Assurance

Quality is central to every process we undertake. Operating under ISO 9001 certified procedures, every weld, fabricated part, and assembled component meets rigorous standards. In-house inspection capabilities include visual checks, dimensional verification, and full material traceability. Certificates of conformity and First Article Inspection Reports (FAIR) are provided with every order, ensuring reliability, compliance, and peace of mind for all clients.

Inspection and Engineering Support

We provide full inspection facilities, including CMM (Coordinate Measuring Machine), Trimos height gauge, surface finish measurement, and hardness testing. First Article Inspection Reports (FAIR) and certificates of conformity are supplied with every order. Our processes ensure flexible production from one-off parts to batch runs, repeatable accuracy across all jobs, and high-quality outcomes managed by experienced engineers. Reverse engineering and R&D support are also available for aerospace, oil and gas, defence, medical, and general engineering applications.

Precision CNC Turning Awaits

Transform Your Designs With Professional Help. Call Today To Book A Consultation And Secure Flawless Machining Outcomes.

%20Ltd_jfif.jpg)